Description

YSJ TECHNOLOGY can produce optical quartz glass windows, it can able to bear high temperature and high pressure, mostly applied to special ray source, optical instrument, etc. It can experiment temperature up to 1200 degree, intenerate temperatures to 1730 degree.

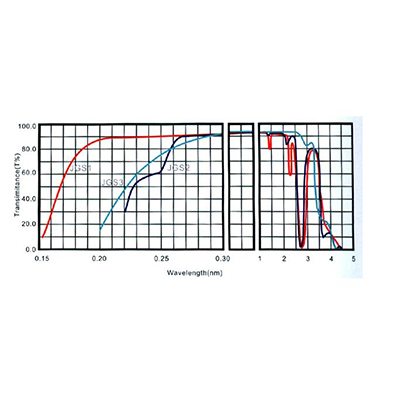

1.JGS1( Extreme UV optical quartz glass)

It is a high-purity optical quartz glass made by oxyhydrogen flame melting. Its satisfactory UV light transmission performance surpass all the other glass types in particular in the shortwave UV zone and can achieve a 90% transmission rate at the wavelength of 185nm. Hence it is an ideal choice for applications in the wavelength range of 185-2500nm.2.JGS2 (UV optical quartz glass)

It is an optical quartz glass made by oxyhydrogen flame melting and is suggested for applications in the wavelength range of 220-2500nm.

3. JGS3 (Infrared quartz glass)

It has a good performance of infrared light transmission with a transmittance of over 85%. It is recommended for applications in the wavelength range of 260-3500nm.

Quartz Windows Specification:

Material:

UV

VIS IR grade Fused Silica

Dimension Tolerance:

+0.0, -0.1mm

Thickness Tolerance:

± 0.1mm

Surface quality:

60/40(Standard), 10/5(High Precision)

Clear Aperture:

>85%

Flatness:

λ(Standard), λ/10(High Precision) per 25mm@633nm

Parallelism:

1' (Standard), 10" (High Precision)

Bevel:

<0.25mm X 45°

Coating:

Upon requirement

Optical constants of Quartz glass

JGS-1

JGS-2

JGS-3

Spectral characteristics

180-2500nm

200-2500nm

260-3500nm

90%

85%

85%

Bubble class

0

2

2

Birefringence

1-2

1-2

1-2

Grain structure

1

2

2

Fringe

1-2

1-2

2

Uniformity

1-2

2

2

Fluorescence

1

2

2

Radiation Performance

Does

not change color

Slight

discoloration

Change

color

The average transmittance

Physical properties of quartz glass

|

|

|

|

Mechanical properties |

Standard value |

|

Density |

2.2g/cm3 |

|

Compressive strength |

1100Mpa |

|

Bending strength |

67Mpa |

|

Tensile strength |

48Mpa |

|

Poisson's ratio μ |

0.14~0.17 |

|

Young's modulus E |

72000Mpa |

|

Rigidity modulus |

31000Mpa |

|

Mohs hardness |

5.5~6.5 |

|

|

|

|

Thermal properties |

Standard value |

|

Transformation point |

1280ºC |

|

Softening point |

1780ºC |

|

Annealing Point |

1250ºC |

|

Specific heat(20~350ºC) |

670J/kg.ºC |

|

Thermal conductivity(20ºC) |

1.4W/m.ºC |

|

Index of refraction |

1.4585 |

|

Coefficient of thermal expansion |

5.5×10-7cm/cm. ºC |

|

Thermal processing temperature |

1750~2050ºC |

|

Short-term use temperature |

1300ºC |

|

Long-term use temperature |

1100ºC |